Maintaining suitable noise levels in a manufacturing or industrial environment often proves challenging as the noise output from machinery can be deafening.

Thankfully, acoustical testing – and subsequent soundproofing – can improve manufacturing facilities’ noise levels to ensure OSHA and noise-ordinance compliance while leading to improved productivity and safety.

TEST

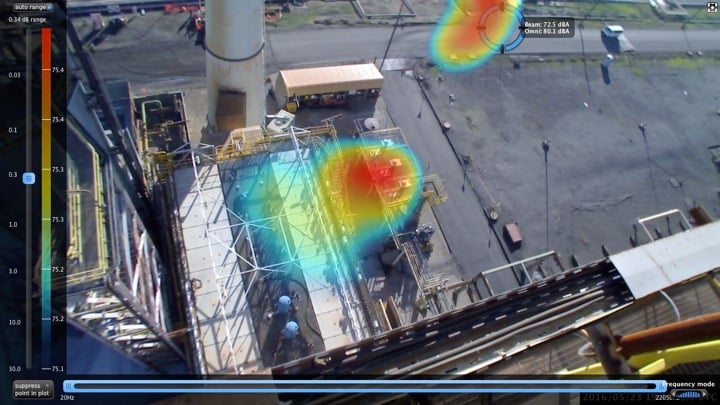

Noise and vibration testing uses a variety of sound level meters, dynamic signal analyzers, microphones, accelerometers or acoustic cameras in order to determine the best and most cost-effective noise and vibration control solutions.

- Room Acoustic Testing and Analysis: This test helps identify the propagation, quality and qualities of sound within a room.

- OSHA Noise Compliance Testing: This test determines if employees are exposed to noise levels that are at or above an eight-hour time-weighted average (TWA) of 85 dBA in accordance with OSHA.

- Community Noise Survey Testing: On behalf of residents, businesses and communities, this test determines community noise-ordinance compliance.

- Acoustical Camera Testing Services: These services are used to identify complex noise-pollution problems where different noise sources impact the client’s environment.

IDENTIFY

Acoustical testing will then help identify the offensive noise, determine the noise transmission path(s) – the source of the noise and determining how it arrives at your ear – and then measure the acoustic characteristics of the noise. Acoustic characteristics of noise include the volume, duration, and frequency of the noise. With this knowledge, it can then be determined how to best manage, reduce, or block the sound energy with soundproofing materials.

RESULTS

Acoustical testing will likely uncover a combination of common industrial noises, such as …

- Airborne: Noise through openings, apertures and other structural gaps Ambient: Background noise occurring naturally

- Flanking: Noise passing around or through heavy, insulated areas into adjacent rooms

- Impact: Noise produced by the collision of two solid objects, like footsteps, dropped objects, etc.

- Impulsive: Single or multiple sound pressure peaks or sharp, short-interval sound pressure peaks

- Masking: Intense noise that can make other sounds inaudible or unintelligible

- Random: An oscillation whose instantaneous magnitude is not specified for any given instant of time

- Structural: Noise created by impact or by vibration

- White: Uniform noise over wide range of frequencies

SOLUTIONS

Once the offending noises and transmission paths are identified, it is then determined how to best address the noise using one or more types of noise-control materials. Soundproofing materials are selected based upon the type of noise and its acoustical characteristics.

By offering a large variety of noise control products, we can reduce noise levels within any size or shape manufacturing or industrial facility. Whether the noise problems are inside the manufacturing facility or outside, we can normally create an effective solution for even the most difficult noise problem to improve working conditions.

Our acoustical testing services are available to audit your facilities with the goals of keeping productivity up and costs down. Contact us today to learn more.